Stabilizing Transport Robot

Senior Capstone Project · 24-671 Electromechanical Systems Design · Fall 2025 · Team of 5

Overview

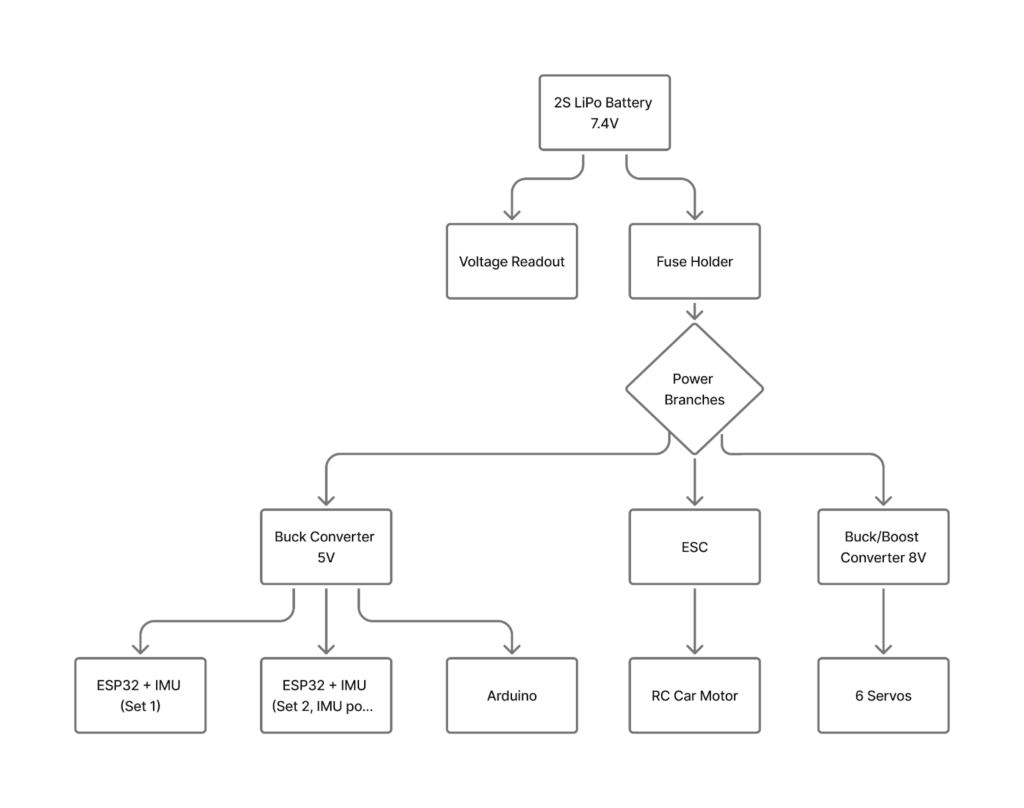

Biological samples, especially live cell cultures, are very sensitive to tilting and vibration during transport. Yet on university campuses, these samples are often still carried by hand or on un-stabilized carts, which expose them to damaging motion. Meanwhile, fully autonomous hospital transport robots exist, but their cost is far beyond what academic labs can justify. Our project addresses this gap: A low-cost robotic platform that stabilizes samples during transport using active tilt compensation and passive vibration isolation.

Our Robot: Active Tilt Compensation + Vibration Attenuation

We designed a hybrid stabilization system:

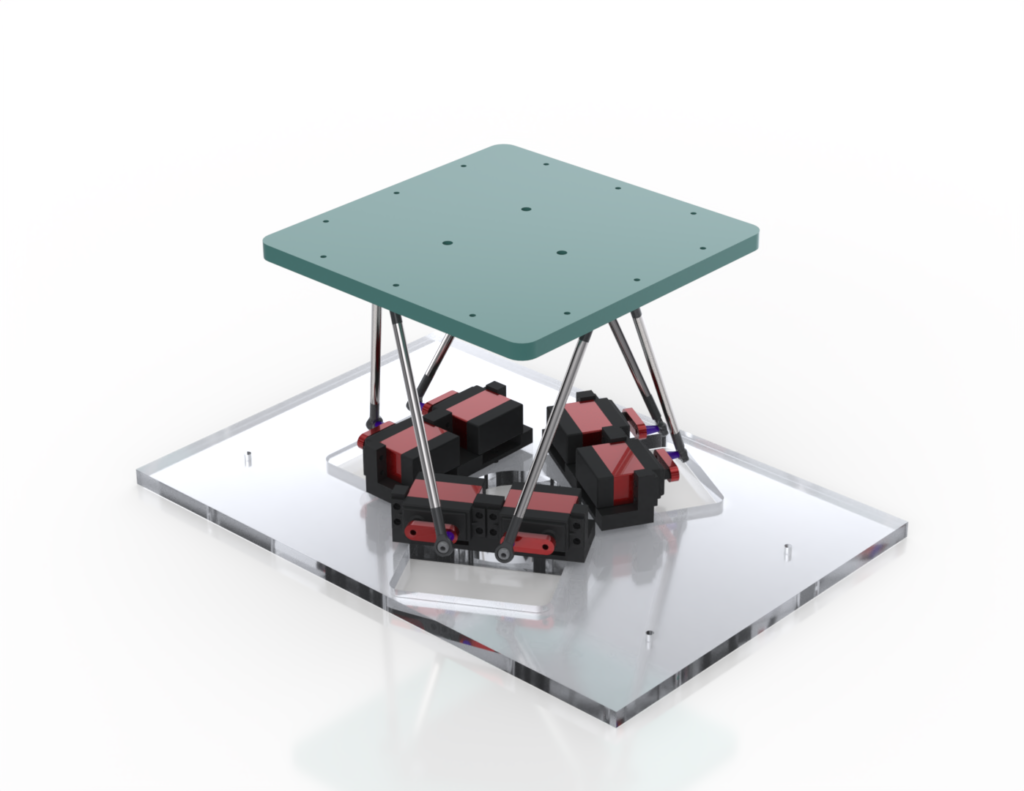

A 6-DOF Stewart Platform actively compensates roll and pitch.

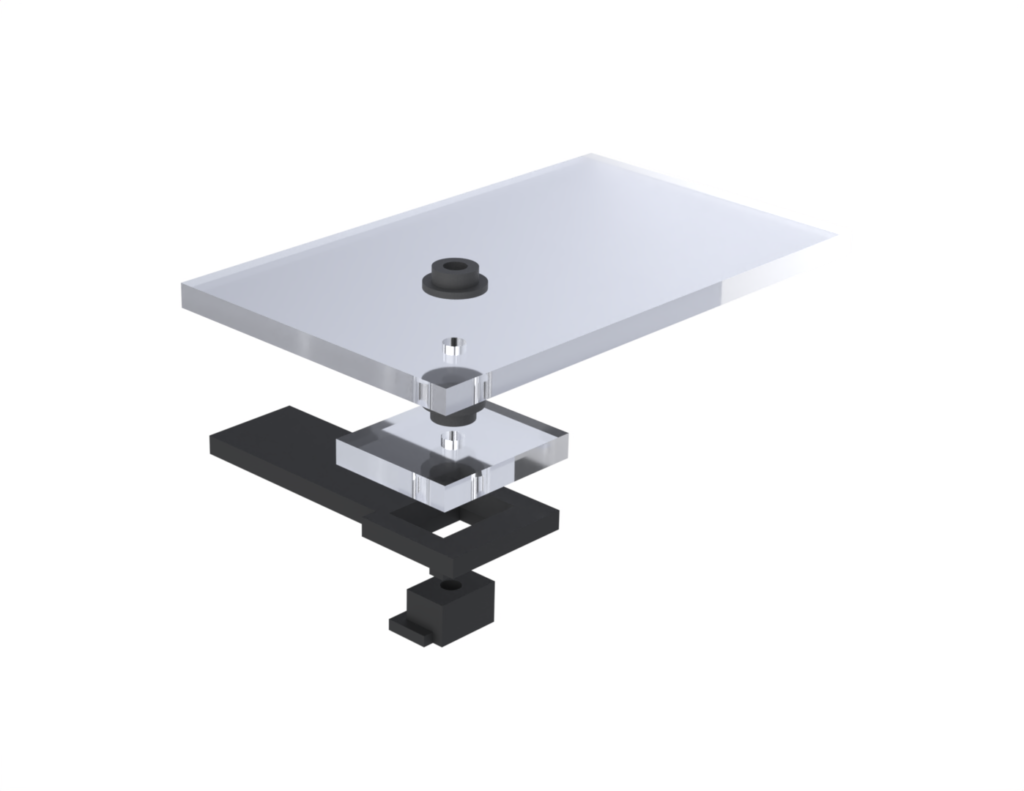

A tuned spring–damper chassis passively reduces transmitted vibration.

Outcomes

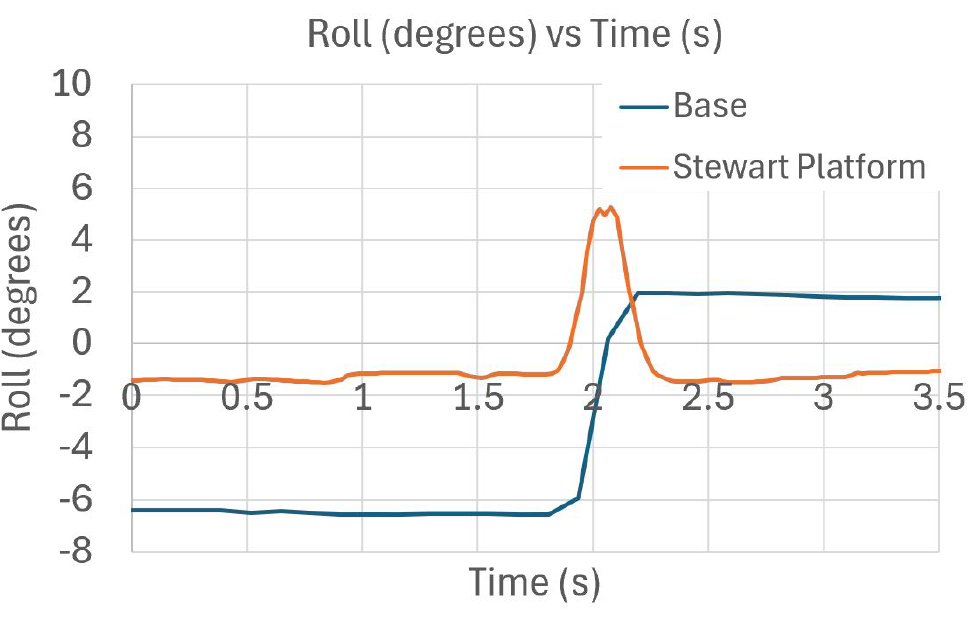

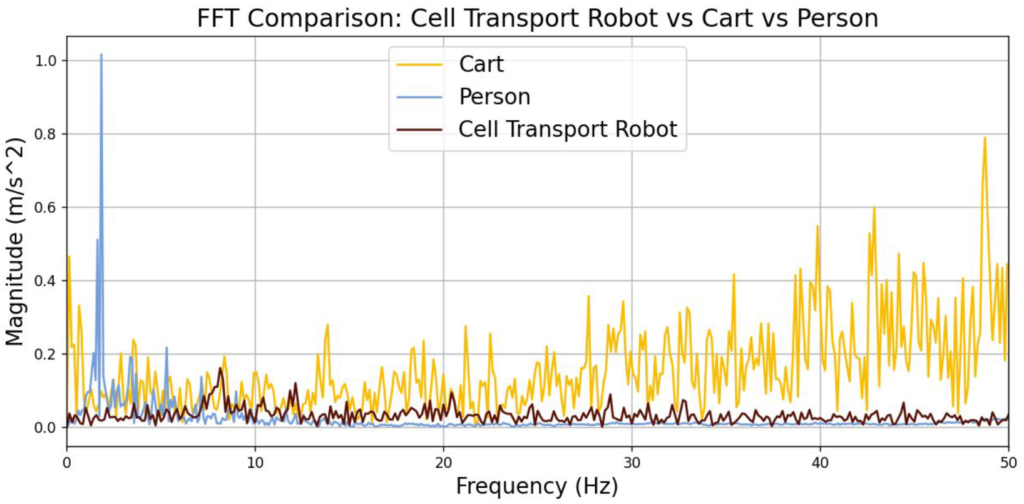

Through a combination of active tilt compensation and passive vibration isolation, the robot reduced transmitted vibration magnitudes by more than 80% compared to both hand-carrying and traditional lab carts. The Stewart platform achieved <1° steady-state error with a 0.5-second response time, enabling reliable stabilization during driving, slopes, and turns, while meeting our maximum correction capability of 20° roll and 23° pitch. These results demonstrated that an affordable, compact system can meaningfully improve the safety and consistency of sample transport in academic research environments. Our work was recognized at the CMU Mechanical Engineering Design Expo, where we received the Best Prototype Award.