Programmable Soft Materials for Regenerative Robotics

School: EPFL

PI: Josie Hughes

Direct Supervisor: Nana Obayashi

Overview

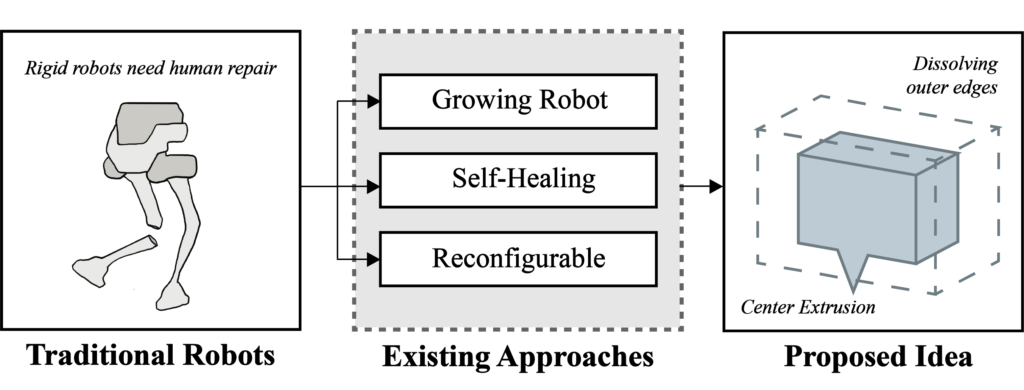

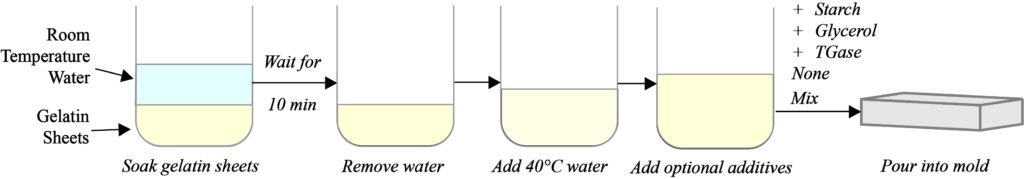

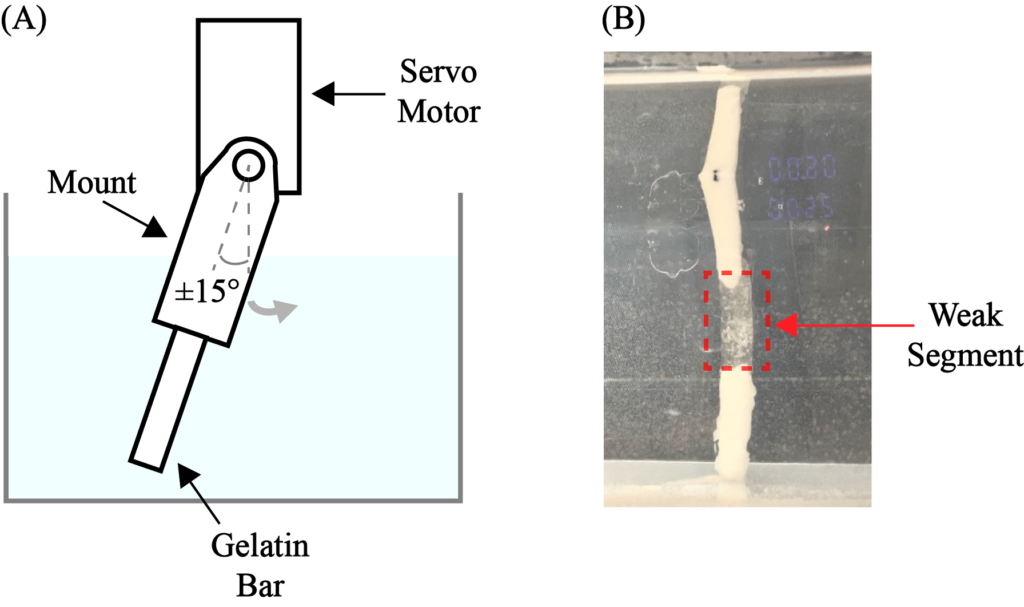

I decided to take on a semester project during my exchange at EPFL in Switzerland, and this is what I worked on! I explored a new materials direction in soft robotics: using tunable gelatin-based materials to create structures that can selectively break down and potentially regenerate. I investigated how different additives (cornstarch, glycerol, TGase) and geometry influence mechanical strength and water response, and I developed structures with embedded weak points that dissolve in predictable ways. Although the project was very exploratory, it introduced me to regenerative robotics, rapid materials experimentation, and hands-on material testing.

Research Question

Can soft robotic structures be designed with embedded “programmable weak points” that dissolve predictably, enabling controlled breakdown and future regrowth?

Contributions

Screened candidate materials (PVA, Soluvlies, cotton candy, gelatin) for dissolution and mechanical behavior.

Developed multiple gelatin-based formulations using cornstarch, glycerol, and TGase for tunability.

Designed and fabricated bars with embedded weak segments using 3D-printed molds.

Built a servo-driven mechanical test rig to evaluate cyclic stress + dissolution.

Measured failure location, water resistance, stretchability, and breakdown dynamics.

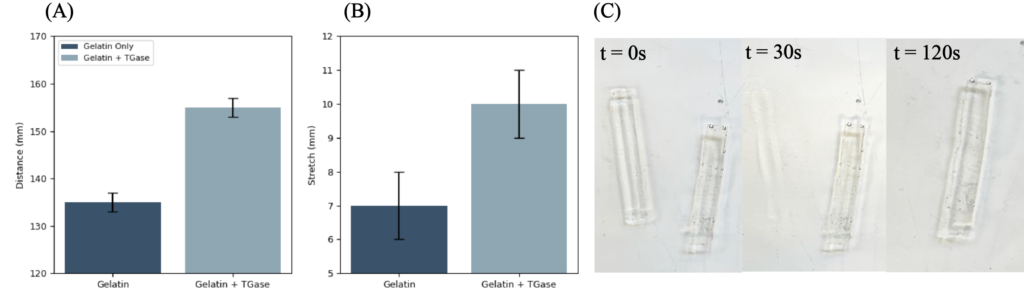

Compared crosslinked vs non-crosslinked gelatin for mechanical strength and water durability.

Documented findings in a full technical report and delivered midterm + final presentations.

Key Findings

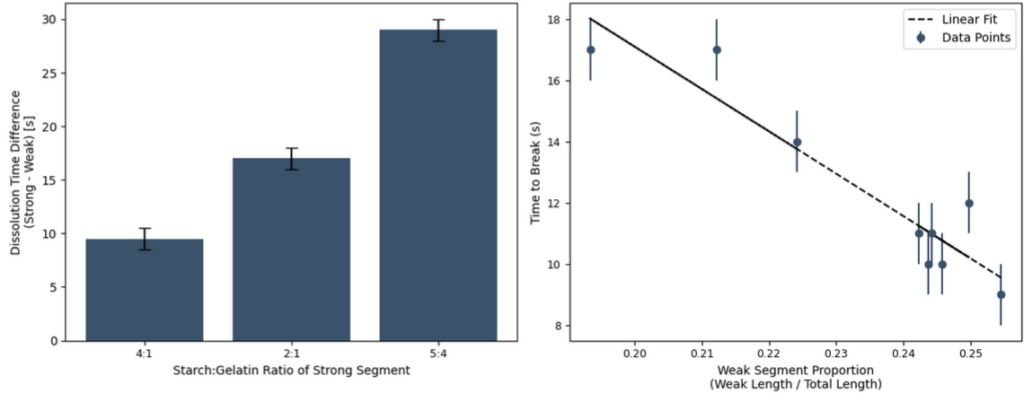

Programmable weak points work — pure gelatin consistently failed first under stress + warm water.

Material tuning matters — increasing cornstarch improved water resistance; larger weak segments broke faster.

TGase crosslinking dramatically improved durability — crosslinked samples resisted stretching and did not dissolve even after minutes in warm water.

Why This Matters

This project establishes a materials foundation for future regenerative robots capable of controlled self-repair and shape recomposition. This is a direction largely unexplored in soft robotics and currently at the front edge of research.